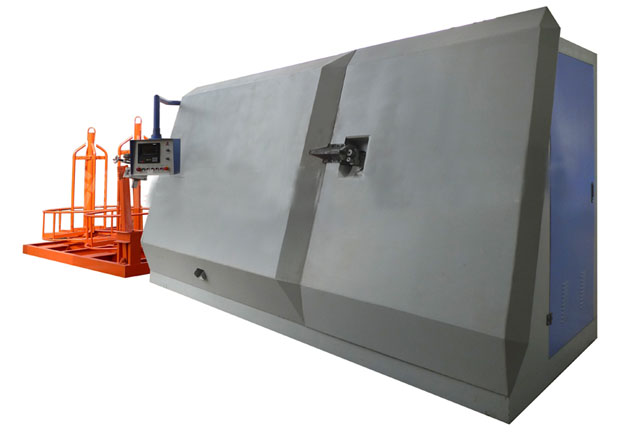

CNC bending hoop machine: steel can be cold-rolled, hot-rolled wire rod, steel rebar straightening - bending - cut a finished product, used for processing structural beams or columns with stirrup, machined directly from the rod stirrup, only 1 people, fast, people and material, and.

Automatic forming, simple and fast, no waste, high automation, greatly improve production efficiency.

Microcomputer control, with color display, friendly interface, should understand.

- NC - hoop bending machine features: straightening system: multi wheel group by our factory for the production of straight machine structure, consists of 2 groups of horizontal and vertical multi wheel straightening, straightening system with position memory testing, replacing steel bars of different diameters, straightening wheel automatically downward or upward to change the rapid adjustment, reinforced straightening (patent technology), shorten the time of steel bar straightening, the whole process can be completed automatically, only 10 rounds of group synchronous traction steel wheel and steel pressure decreases, and the traction force is small, energy consumption, reduce the loss of steel.

The CNC bending hoop machine features two: cutting system: cut off the configuration without brake brake control device (the device factory is my invention), support high frequent starting cut, make the reliability, greatly improving the durability.

The CNC bending hoop machine features three: bending: imported servo motor to drive, bending arms can rotate quickly and telescopic, the General Factory (bending structure imitation imported) eccentric shaft type into straight reciprocating structure, remove eccentric parts loss.

The CNC bending hoop machine features four: control system: the use of advanced PLC control, color touch screen display, key input, reduce the difference caused by environmental damage to the touch screen, built-in a variety of different shapes of hoop graphics, key parts imported brand-name products. It has the function of fault identification and alarm.

CNC bending machine - features five: console: in order to reduce the operating space occupied by the surrounding space, the control cable unsafe in the ground. The new model designs the operating panel on the mainframe and can move around.

| Model |

WGJY12-12A

Hydraulic model |

WGJD12-12A

General type |

YDWGJD12-12A

Mobile |

ZWGJD12-10A

Cold rolling bending hoop integrated machine |

WGJD16-16A

Large diameter |

| Single line machining capability(mm) |

Φ5-12 |

Φ5-12 |

Φ5-12 |

Φ5-12 |

Φ8-16 |

| Diameter of finished steel bar(mm) |

Φ5-12 |

Φ5-12 |

Φ5-12 |

Φ5-10 |

Φ8-16 |

| Maximum bending angle(° ) |

180 |

180 |

180 |

180 |

180 |

| Central axle diameter (mm) |

Φ25-32 |

Φ25-32 |

Φ25-32 |

Φ25-32 |

Φ25-50 |

| Maximum tractive speed(m/min) |

50-80 |

50-120 |

50-120 |

50-120 |

50-100 |

| Maximum bending speed(°/sec) |

0-600 |

0-1000 |

0-1000 |

0-1000 |

0- 800 |

| Length accuracy(mm) |

±1.5 |

±1 |

±1 |

±1 |

±1 |

| Angle accuracy(°) |

±1 |

±1 |

±1 |

±1 |

±1 |

| Drive mode |

two-wheel drive |

10 drive wheels drive |

10 drive wheels drive |

10 drive wheels drive |

10 drive wheels drive |

| Average consumption of electricity(kw/h) |

4.5 |

4.5 |

4.5 |

4.5 |

15 |

| Equipment size(mm) |

2600*1800*1000 |

4500*2200*1400 |

4500*2200*1400 |

4500*2200*1400 |

6500*2200*1500 |

| Equipment power(kw) |

5.5 |

11 |

11 |

55 |

30 |

| Working environment temperature(℃) |

-5 --40 |

-5 --40 |

-5 --40 |

-5 --40 |

-5 --40 |

| Equipment weight(kg) |

800 |

2300 |

2800 |

8000 |

7000 |